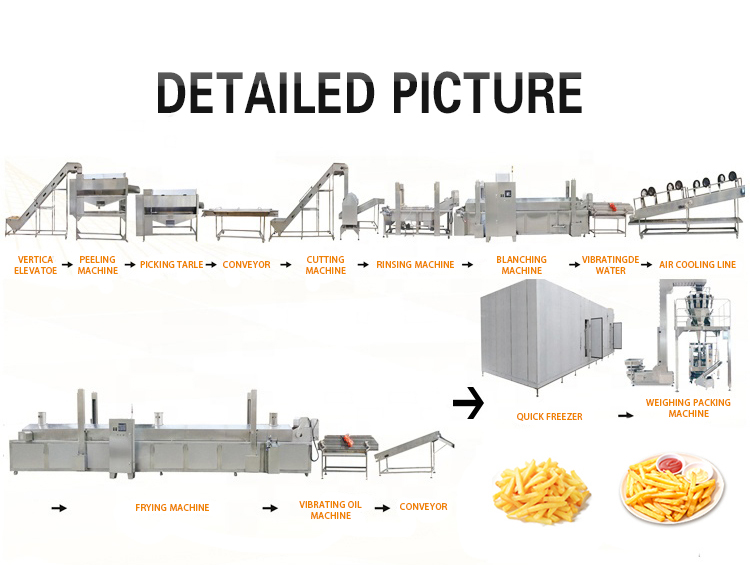

Process flow:

hoisting to feed → wash and peel → select and trim → hoisting to feed → slicing (strip) → rinsing → blanching and color protection → dehydration → frying → deoiling→ seasoning → conveying → package. The equipment adjustment process can make deep-fried quick-frozen French fries. ◆ This set of equipment is made of 304 stainless steel, high yield, save labor, on site installation and commissioning. automatic frozen french fries / potato chips production line frozen french fries production capacity from 200kg/h to 2000kg/h,2kg potato produce 1kg frozen french fries potato chips production capacity from 100kg/h to 500kg/h, 4kg potato produce 1kg potato chips.| No | Name | Power | Dimension |

| 1 | Conveyor | 0.75kw | 3000*1000mm |

| 2 | Washing peeling machine | 3.75kw | 3000*1200mm |

| 3 | Picking line | 0.75kw | 2000*1000mm |

| 4 | Cutter machine | 3kw | 1000*800mm |

| 5 | Washing machine | 4kw | 4200*1200mm |

| 6 | Blanching machine | Customized | Customized |

| 7 | air drying machine | 3kw | 5000*1000mm |

| 8 | Fryer machine | Customized | Customized |

| 9 | Deoil machine | 0.11kw | 1500*1000mm |

| 10 | air cooling Conveyor | 2.5kw | 4500*1000mm |

| 11 | IQF Freezer machine | Customized | Customized |

| 12 | Packing machine | Customized | Customized |

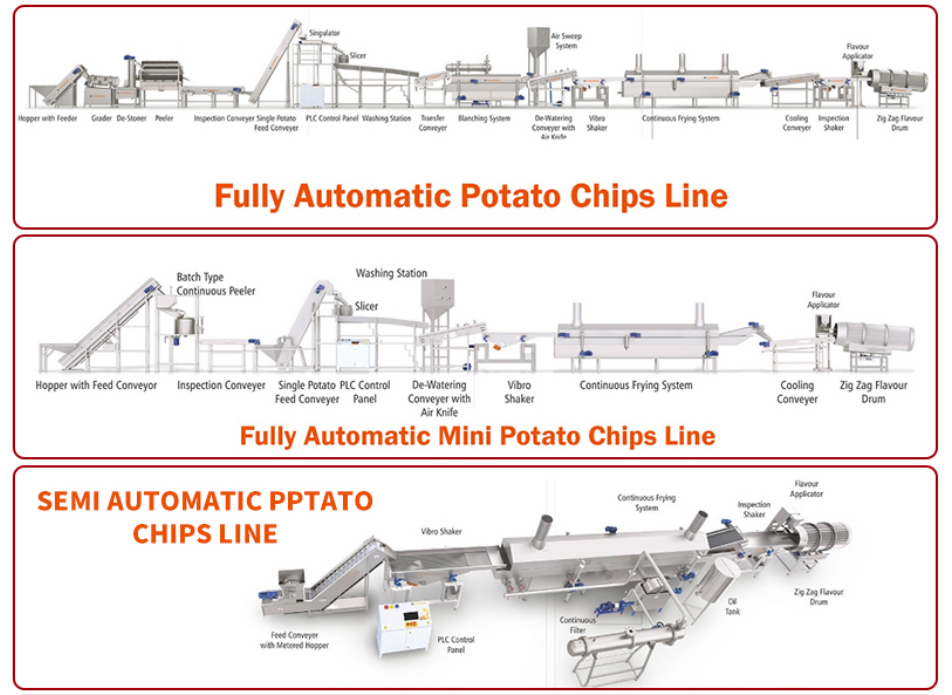

french fries and potato chips production line advantages.

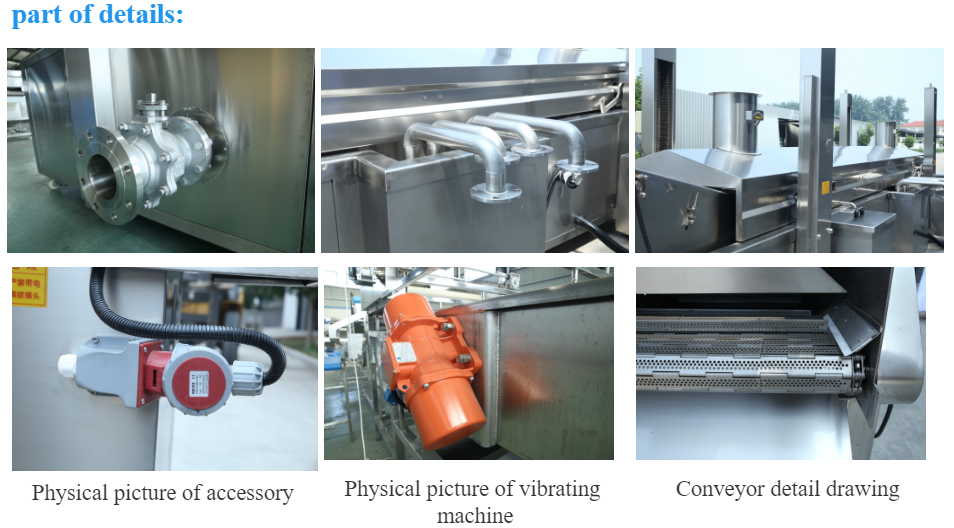

1.compact dimension can save the space of the food factory and not influence the capacity. 2.beautiful Appearance design and premium quality stainless steel SUS 304, easy cleaning, HACCP requirements. 3.we have ten years of french fries production line experiences.Over sea install and maintain service can be provided. and The line can be design according to customer’s thinking and factory sizes. We can provide full production guidance,decade .of our customer. 4.All line can implement automation control.Central control electrical box can control the frying time 、frying temperature and so on. 5.We can produce and customize separate frying machine, cleaning and peeling machine and other machines.| DEVICE NAME | Model | Dimension(mm) | Power | Material |

| Hoister with tank | TSJ-3400*500 | 5000*1200*3000 | 0.75kw | SUS304 |

| Washing peeling machine | QPJ-2400 | 2800*950*1670 | 4.55KW | SUS304 |

| Picking line | TJX-2500 | 2500*1100*1100 | 0.55KW | SUS304 |

| Washing &conveyor | TSJ-3500 | 0.55KW | SUS304 | |

| Washing flow tank | QXJ-4200 | 4200*1200*1600 | 1.5kw | SUS304 |

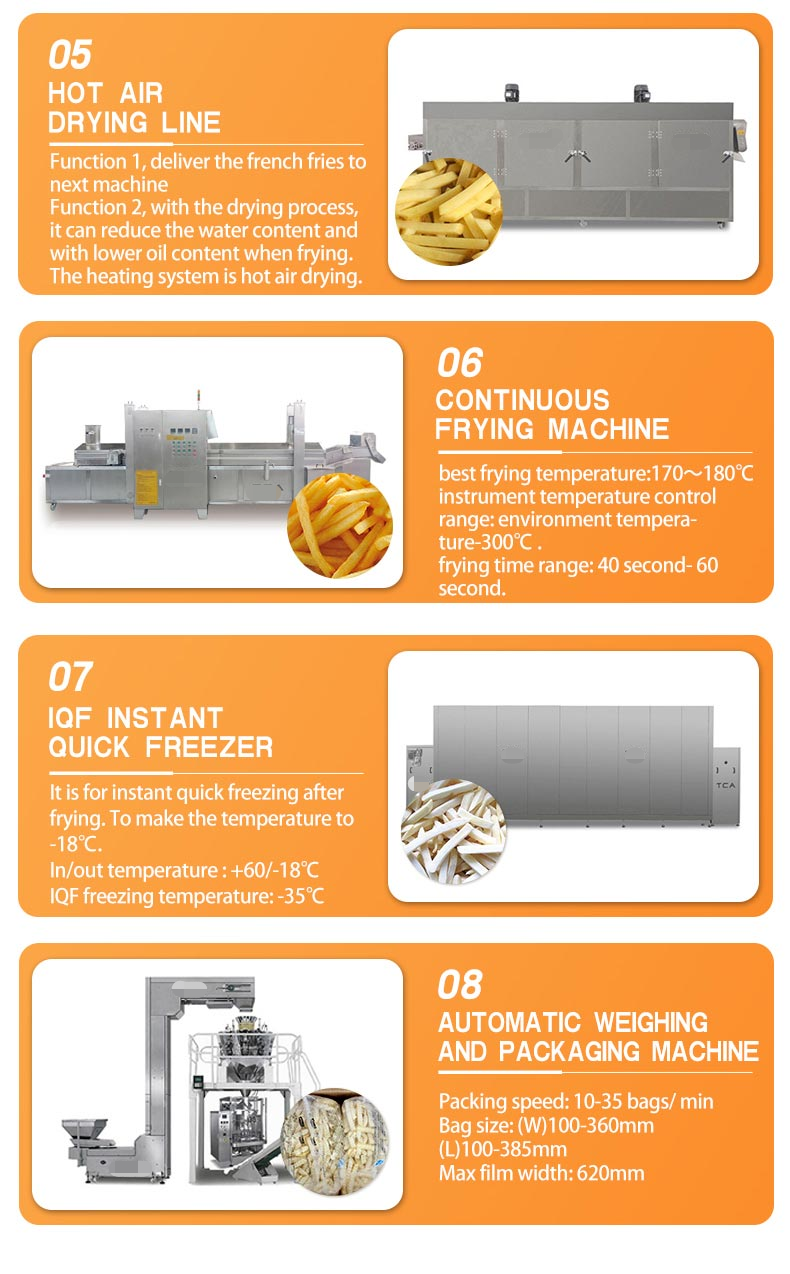

| Drying line | FGX-3000 | 3000*1100*1800 | 3KW | SUS304 |

| Fast conveyor | SSJ-2000 | 2000×820×1370 | 0.75KW | SUS304 |

| Continuous frying machine | SSJ-2000 | 6500*2300*2200 | 10.5KW | SUS304 |

| Vibrating deoil machine | ZDS-1500 | 1500*1100*1100 | 0.37KW | SUS304 |

| Conveyor | SSJ-2500 | 2500*1200*1800 | 0.55KW | SUS304 |

| Seasoning machine | TWJ-2500 | 3000*1100*1700 | 0.75KW | SUS304 |

| automatic packaging machine | 420 | 1400*970*1600 | 2.2kw | SUS304 |

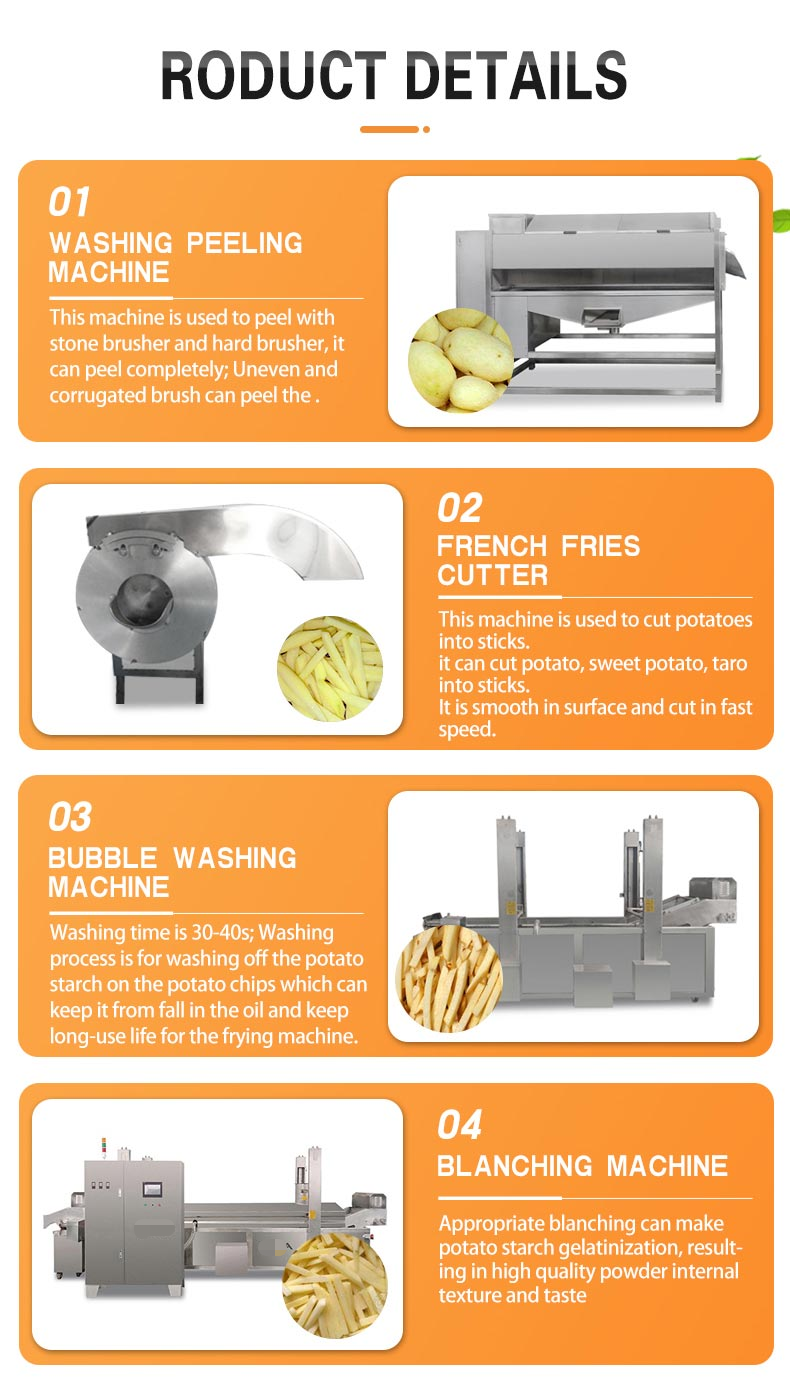

Steam drying technology is adopted.By heating them with a steady stream of steam, it can remove the amount of water on the surface and moisture from the inside

Steam drying technology is adopted.By heating them with a steady stream of steam, it can remove the amount of water on the surface and moisture from the inside In this step,flaw potato can be picked out and make it return to washing peeling machine. All material is Stainless steel.

In this step,flaw potato can be picked out and make it return to washing peeling machine. All material is Stainless steel. Blanching is a necessary procedure. It can destroy the enzyme activity, and improve the organizational structure.protect the product's color.

Blanching is a necessary procedure. It can destroy the enzyme activity, and improve the organizational structure.protect the product's color. This machine is used to cut potatoes into sticks.it can cut potato, sweet potato,.Easy to wash and easy to operate.Save labor and cost.it can wash off the sugar on the surface of the chips so that keep the oil from turning bad and keep a long using life. fries is totally immersed in water which can keep it from enzymatic-oxydative browning;

This machine is used to cut potatoes into sticks.it can cut potato, sweet potato,.Easy to wash and easy to operate.Save labor and cost.it can wash off the sugar on the surface of the chips so that keep the oil from turning bad and keep a long using life. fries is totally immersed in water which can keep it from enzymatic-oxydative browning; Attributes of making potato french fries processing line:

Attributes of making potato french fries processing line: | making potato french fries processing line | making potato french fries processing line | making potato french fries processing line | |

| 1 | Conveyor hoist machine | 0.75kw/380v/50Hz | 2000x800x2000mm |

| 2 | Cleaning and peeling machine | 4.75kw/380v/50Hz | 1800x900x1500mm |

| 3 | Picking line | 0.75kw/380v/50Hz | 3000x900x900mm |

| 4 | French fries potato chip machine | 1.5kw/380v/50Hz | 950x800x950mm |

| 5 | Washing machine | 5kw/380v/50Hz | 3000x1600x900mm |

| 6 | Blanching machine | 70kw/380v/50Hz | 3000x1600x950mm |

| 7 | Vibration water remover machine | 1.5kw/380v/50Hz | 1500*1000*1300mm |

| 8 | Picking line | 0.75kw/ 380V/50Hz | 3000x800x1000mm |

| 9 | Air cooled dewatering machine | 15kw/380v/50Hz | 4000x1200x1400mm |

| 10 | Conveyor hoist machine | 0.75kw/380v/50hz | 2000*800*1300 |

| 11 | Electric heating frying line | 203kw/380v/50Hz | 3500x1200x2600mm |

| 12 | Vibration oil remover machine | 1.5kw/380v/50Hz | 1500x1000x1300mm |

| 13 | Air dryer | 8kw/380v/50Hz | 4000x1200x1600mm |

| 14 | Conveyor hoist machine | 0.75kw/380v/50Hz | 2000x800x2200mm |

| 15 | Seasoning machine | 1.5kw/380v/50hz | 2000*700*1600 |